Fiber laser cutting is used to cut a variety of different materials, including stainless steel, aluminium, copper, brass, and non-metal products. This equipment produces a high-power focused laser beam that uses a thermal reaction to quickly melt, evaporate, or cause ablation. But how does this actually work?

What Is the Function of Fiber Laser Cutting?

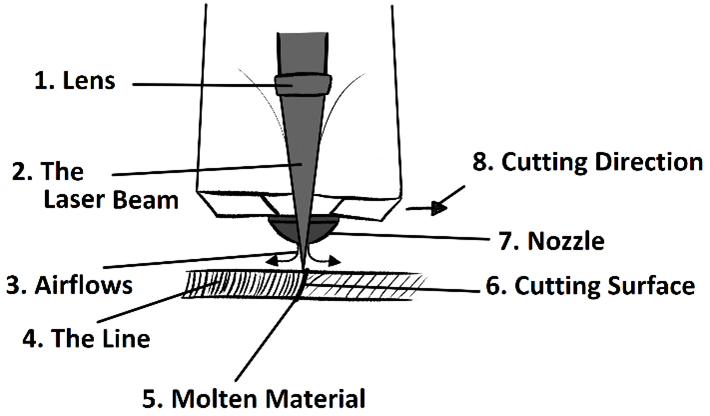

Fiber laser cutting machines are used for the high precision cutting of metal materials into high quality metal parts. By irradiating a work surface with a laser, the beam energy is absorbed and transferred into heat energy. That means the irradiated spot has a temperature that increases quickly, to the point where it is melted and vaporized into a micro pit. Thermal diffusion then melts the metal around it, causing the pit to expand and create a miniaturized explosion. The material is ejected at a rapid rate and creates an anti-shock wave. Therefore, the material is shaped with precise, quality cuts.

What Type of Fiber Laser Cutters Are There?

Fiber laser cutters are useful for cutting thin pieces of material without incurring tooling costs. That means they can be used for laser processing small batches of parts. It is common for fiber laser cutting technology to utilize a computerized, digital control system, also known as a CNC.

Previously, a CO2 laser may have been used for fiber optics, however nowadays it is better to use a fiber laser cutter for a more precisely cut edge.

How Does a Fiber Laser Work?

Ultimately, the fiber laser cutter uses a stream of solid-state diodes to create a heated beam. That means it is much more efficient at thin plate cutting compared to CO2 lasers and YAG lasers. In fact, in terms of its sheet metal cutting ability, fiber laser cutting is around 2-4 times faster than a CO2 laser.

An optical fiber laser has a wavelength of around 1.06 µm. Therefore, it is extremely effective on highly reflective materials. You will find that the best materials for fiber laser cutting include carbon steel and metal alloys.

Safety and Fiber Laser Cutting

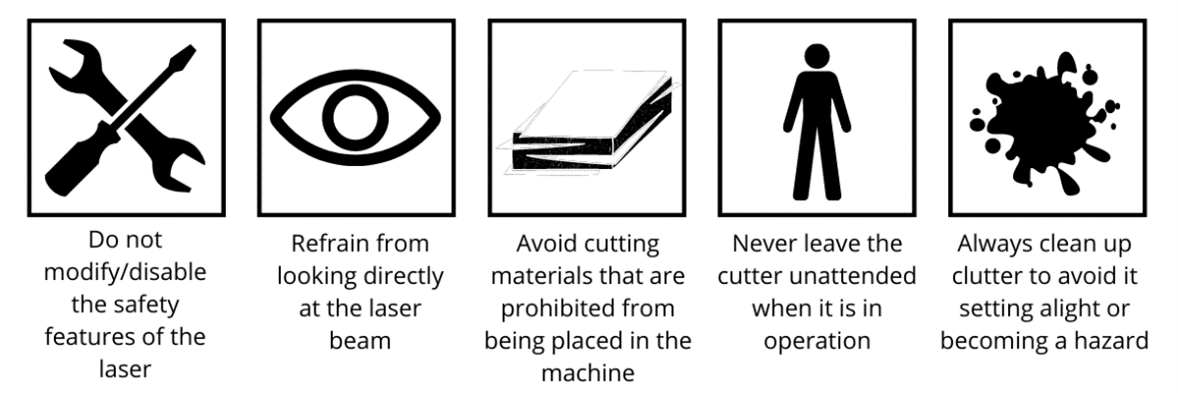

If you intend to use a fiber laser cutting device, it is important that you follow the right safety precautions to ensure the success of your experiment:

- Always wear PPE, such as eye protection

- Avoid turning off the safety features of your laser cutter

- Do not look directly at the laser beam

- Do not put flammable objects in the machine

If you fail to adhere to safety procedures, you may end up sustaining physical injuries, including getting burned. Naturally, there are significant purchasing and installation costs to consider when choosing whether to purchase a fiber laser cutting machine. It is typically safer and more cost-effective to depend on a profiling service provider.

Do You Need a Professional Fiber Laser Cutting Service?

Armortex has a variety of fiber laser cutting devices at our disposal. All of them have advanced cutting capabilities to provide a smooth cut edge. Find out more by contacting our team of specialists at 1-800-880-8306 or info@armortex.com.