Waterjet cutting is an erosion technique used to shape a range of materials into specific profiles. It is based on a combination of high pressure water and an abrasive; creating an ideal resource for ensuring a precise cut of machinery parts and fabrication items. It can be used for reaming, cutting, carving and shaping. Waterjet cutting is a great way to personalize both essential equipment and parts. Here are the main benefits of this type of cutting system.

How Does a Waterjet Cutter Work?

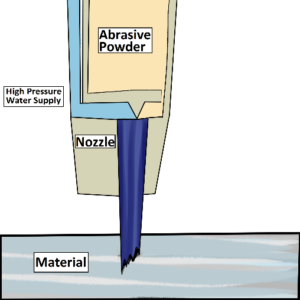

The purpose behind a cutting stream is to accelerate the process of erosion. Water is shot through a nozzle made of diamond or ruby into a mixing chamber at a high velocity. The mixing chamber has a high-pressure pump that emits a jet of water after the liquid has been mixed with an abrasive powder. Usually, this powder is sand, but it could also be in a form of suspended grit, as long as it contains abrasive particles. The mixed water is then fired at the material and used to erode it into specific shapes.

Here are some benefits of waterjet cutters:

Waterjet Cutting and Materials

One of the best things about waterjet cutting is that it can be used on a wide variety of materials. This selection of materials can be extremely diverse and can range from metals to plastics, for example, titanium to polyethylene plastic. This type of high-pressure water system is precise and can make professional cuts on materials that are up to 200mm thick.

Lack of Heat

Waterjet cutting is known as a cold cutting process. That means that it is less likely to damage or malform the intrinsic properties of the material because there will be no heat-affected zone (HAZ).

Environmentally Friendly

Waterjet cutters are the greenest form of cutting tools. This is due to the fact that they do not produce any hazardous waste. Any scrap metal that is produced can be easily recycled.

Precise Cutting

Thanks to the precise cutting stream of the waterjet cutting tool, it is possible to have a margin of error of only 0.13mm. That means that it can also accurately create a wide variety of shapes.

Do You Need a Waterjet Cutting Machine ?

Waterjet cutting is extremely useful if you are looking for a powerful tool to profile various workpieces. Armortex has a variety of waterjet cutting services available, and we provide waterjet cutting services on demand. Find out more about how our team of specialists can help you by contacting Armortex at 1-800-880-8306 or by emailing info@armortex.com. We are ready to help you find the perfect waterjet cutting technology for your project.